| +81-3-3614-4100 |

|

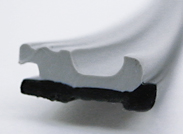

Plastic Extrusion (Co-extrusion)

|

|

Co-extrusion is a process that allows the combination of different materials.

The soft part is suitable for sealing, and the hard part is suitable for

mounting. The hardness of the soft materials can be chosen ranging from

25 to 95°(Japan Industrial Standards hardness).Various materials can be

selected. (PVC, TPO, SBC, EVA, etc.)

Applications Automotive : Weather strip, Glass run channel, Cable protector, etc. Building : Glazing gasket, Air-tight gasket, Sealing materials, etc. Construction machinery : Deflector Appliance : Packing |

|

|

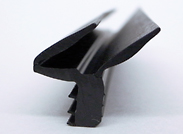

Plastic Extrusion (Triplex-extrusion)

|

|

Triplex-extrusion is a process that allows the combination of different materials. The soft part is suitable for sealing, and the hard part is suitable for mounting. Many surface patterns can be chosen according to the design of the product. Sube-up (smooth-surface layer) is also available. Various materials can be selected. (PVC, TPO, SBC)

Applications Automotive : Weather strip, Glass run channel, Cable protector, etc. Building : Glazing gasket, Air-tight gasket, Sealing materials, etc. Construction machinery : Deflector Appliance : Packing |

|